Products Center

Contact Us

Guangzhou Dingli Storage Equipment Co., Ltd.

TEL:020-82002201

TEL:18102581498

E-MAIL:dlcc168@163.com

ADD:Youbao Industrial Park, No.17 Xiangshan Middle Road, Science City, Huangpu District, Guangzhou

Number of views:

1027

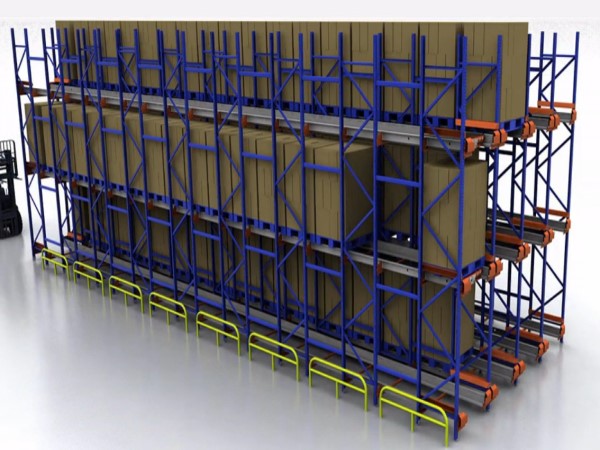

Shuttle Rack

Retail price

0.0

元

Market price

0.0

元

Number of views:

1027

Product serial number

Quantity

-

+

Stock:

Product description

Parameters

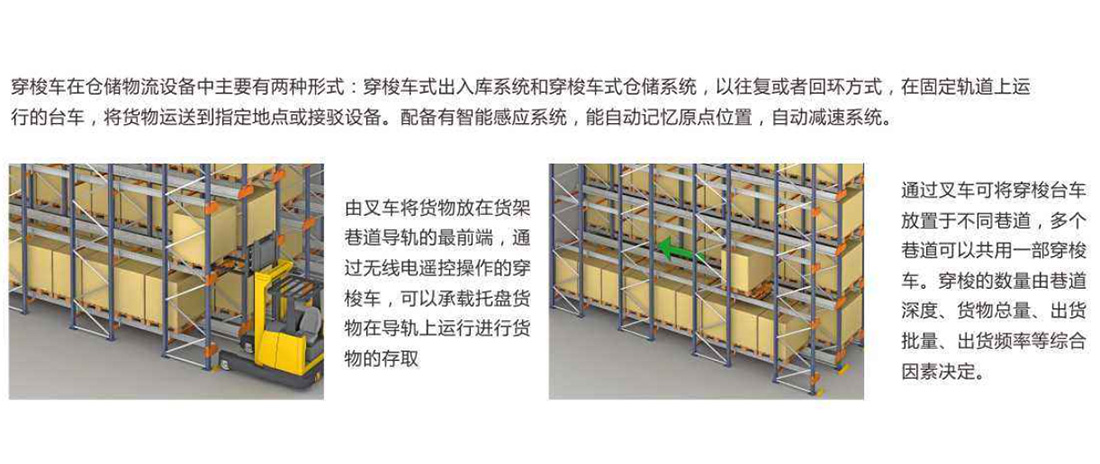

Shuttle shelf characteristics: forklift does not need to enter the roadway, save time, improve the safety of personnel and goods, goods access efficiency, warehouse make full use of the warehouse space, about 80%~85 space; suitable for different kinds of products can be layered flexible access; compared with the frame, through the frame, stable structure root, high safety factor can achieve the first and advanced out; automatic sorting and inventory.

The organic combination of the shuttle and storage shelves formed the shuttle shelves. It can be said that from here, the automation form of storage equipment began to enter a new level.Based on flexible design, shuttle shelves also have several types of solutions, depending

The organic combination of the shuttle and storage shelves formed the shuttle shelves. It can be said that from here, the automation form of storage equipment began to enter a new level.Based on flexible design, shuttle shelves also have several types of solutions, depending

helf Benefits

Shuttle shelf system is a high-density storage system composed of shelves, trucks and forklifts. This efficient storage method is to improve the utilization of warehouse space and bring a new storage choice to customers!Features of the shuttle shelves:

High-density storage, and high warehouse utilization rate.

High work efficiency, greatly reduce the job waiting time.

Flexible operation mode, the access mode of goods can be advanced first out, or advanced after out.

High safety factor, reduce the collision between shelves and forklift, and improve safety productivity.

Lighting requirements are relatively low, with less overall investment compared to other types of shelves

Technical parameters

Capacity: 1000~1500kg

Operating speed: no-load of 0.7-0.9 m / s

Car

Operating speed: full load of 0.6-0.8 m / s

Power unit: lithium-manganese battery or lithium battery

Rated voltage: 24V

Battery life: Normal service time is more than 8 hours

Induction range: Remote control sensing range of 50 m (theoretically 100 m, up to 200 m, but depending on the site environment)

Scope of application

More quantities and less samples: food, drinks, chemical industry, tobacco and other single varieties in large quantities,

A relatively single product industry

Cold storage operation: reduce the low-temperature operation time, improve the work efficiency and operation safety

Term management: warehouse with strict requirements for item batch and first-and-first operation management

Increase storage capacity: storage with limited storage space

Product characteristics

The ▲ storage system is fast and scalable for turnaround boxes or cartons weighing up to 35kg

▲ with double-layer lifting system, excellent system performance

The ▲ lift system and shuttle are equipped with duplex stations for high performance

The ▲ assigned 2 stations for the lift system and the shuttle

▲ height: 6-15m, storage layer 8-36 layer

▲ Length: 20-100m,

▲ optimized shelf design stores cartons or turnover boxes

▲ access double loop improves greater efficiency

The ▲ is equipped with two hoists per roadway for increased efficiency

▲ scalable lifting performance

The ▲ shuttle is simple and ergonomically maintained

▲ has a short investment return on period and strong profitability

Shuttle shelf system is a high-density storage system composed of shelves, trucks and forklifts. This efficient storage method is to improve the utilization of warehouse space and bring a new storage choice to customers!Features of the shuttle shelves:

High-density storage, and high warehouse utilization rate.

High work efficiency, greatly reduce the job waiting time.

Flexible operation mode, the access mode of goods can be advanced first out, or advanced after out.

High safety factor, reduce the collision between shelves and forklift, and improve safety productivity.

Lighting requirements are relatively low, with less overall investment compared to other types of shelves

Technical parameters

Capacity: 1000~1500kg

Operating speed: no-load of 0.7-0.9 m / s

Car

Operating speed: full load of 0.6-0.8 m / s

Power unit: lithium-manganese battery or lithium battery

Rated voltage: 24V

Battery life: Normal service time is more than 8 hours

Induction range: Remote control sensing range of 50 m (theoretically 100 m, up to 200 m, but depending on the site environment)

Scope of application

More quantities and less samples: food, drinks, chemical industry, tobacco and other single varieties in large quantities,

A relatively single product industry

Cold storage operation: reduce the low-temperature operation time, improve the work efficiency and operation safety

Term management: warehouse with strict requirements for item batch and first-and-first operation management

Increase storage capacity: storage with limited storage space

Product characteristics

The ▲ storage system is fast and scalable for turnaround boxes or cartons weighing up to 35kg

▲ with double-layer lifting system, excellent system performance

The ▲ lift system and shuttle are equipped with duplex stations for high performance

The ▲ assigned 2 stations for the lift system and the shuttle

▲ height: 6-15m, storage layer 8-36 layer

▲ Length: 20-100m,

▲ optimized shelf design stores cartons or turnover boxes

▲ access double loop improves greater efficiency

The ▲ is equipped with two hoists per roadway for increased efficiency

▲ scalable lifting performance

The ▲ shuttle is simple and ergonomically maintained

▲ has a short investment return on period and strong profitability

Previous

Shuttle Rack

Next

Shuttle Rack

More Products

Drive-in Rack

Double-depth shelves, as the name suggests, are to add a row of shelves behind the ordinary shelf-type shelves, and use a special forklift with telescopic fork function to easily access the goods. When storing, you need to store the goods in the back position first, and then the front position can be used. When picking up the goods, on the contrary, first take out the goods in the front position. This design can save half of the number of shelf aisles compared with ordinary shelf-type shelves.

Double Depth Shelf

Double-depth shelves, as the name suggests, are to add a row of shelves behind the ordinary shelf-type shelves, and use a special forklift with telescopic fork function to easily access the goods. When storing, you need to store the goods in the back position first, and then the front position can be used. When picking up the goods, on the contrary, first take out the goods in the front position. This design can save half of the number of shelf aisles compared with ordinary shelf-type shelves.

Cantilever Rack

Cantilever is a category of storage racks. It adopts special profile column and high-strength cantilever. It is suitable for storing various long materials, ring materials, plates and irregular materials. The forward cantilever can be single-sided or double-sided. It has the characteristics of light structure and good load capacity. The single arm can carry up to 1000kg. The specially reinforced column structure can withstand 2000~3000kg pressure.

Cantilever Rack

Cantilever is a category of storage racks. It adopts special profile column and high-strength cantilever. It is suitable for storing various long materials, ring materials, plates and irregular materials. The forward cantilever can be single-sided or double-sided. It has the characteristics of light structure and good load capacity. The single arm can carry up to 1000kg. The specially reinforced column structure can withstand 2000~3000kg pressure.

Cantilever Rack

Cantilever is a category of storage racks. It adopts special profile column and high-strength cantilever. It is suitable for storing various long materials, ring materials, plates and irregular materials. The forward cantilever can be single-sided or double-sided. It has the characteristics of light structure and good load capacity. The single arm can load up to 1000kg. The specially reinforced column structure can withstand 2000~3000kg pressure. The back pull design increases the overall stability of the shelf, easy to install, and complete accessories. Combined structure, special profile column, designed back pull to increase stability, equipped with high-strength cantilever (arm can be single-sided or double-sided), with light structure, good load capacity, and high space utilization; after adding a shelf, special It is suitable for warehouses with small space and low height. It is easy to manage and has a wide view. Compared with ordinary shelf racks, it has a higher utilization rate. According to the carrying capacity, it can be divided into three types: lightweight, medium and heavy.

Cantilever rack

Cantilever is a category of storage racks. It adopts special profile column and high-strength cantilever. It is suitable for storing various long materials, ring materials, plates and irregular materials. The forward cantilever can be single-sided or double-sided. It has the characteristics of light structure and good load capacity. The single arm can carry up to 1000kg. The specially reinforced column structure can withstand 2000~3000kg pressure.

020-82002201

TEL:

18102581498

Address: Youbao Industrial Park, No.17 Xiangshan Middle Road, Science City, Huangpu District, Guangzhou

COPYRIGHT © 2020 Guangzhou Dingli Storage Equipment Co., Ltd. ALL RIGHTS RESERVED. 粤ICP备18086819号 Chinese(中文版)